In this article, we’ll give you an overview on what it takes to get started in RSLogix 5000 or Studio 5000 which is an environment of programming ControlLogix & CompactLogix Allen Bradley PLCs. Focus your learning objectives on principles rather than the details of the platform.

In other words, if you learn how to work with Allen Bradley PLCs, you’ll be able to easily reapply your knowledge toward the Siemens platform. We strongly believe that the fundamentals of PLC programming will be reapplicable between platforms.

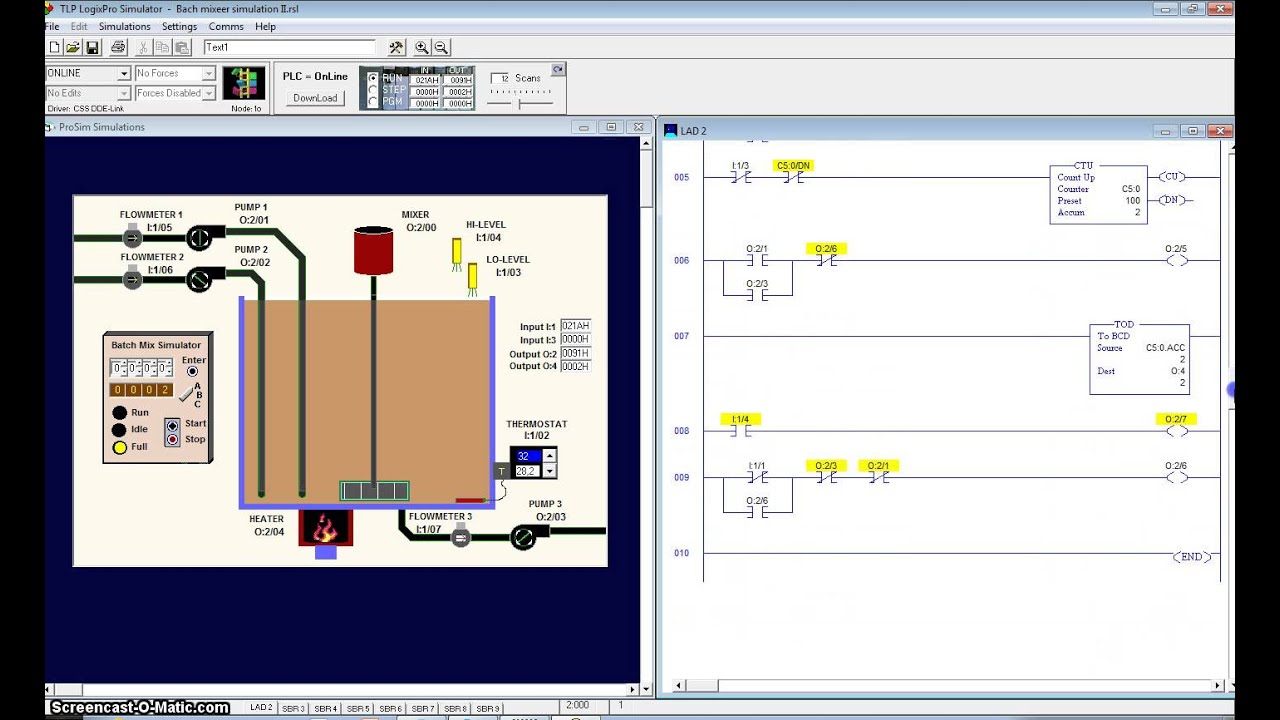

They’re all different, yet similar to each other. There are many flavors & brands of PLCs: Allen Bradley, Mitsubishi, Omron, Siemens and others. We believe that with enough dedication, anyone can learn how to work with PLCs and apply this skill toward a rewarding career in industrial automation. Our goal is to make this skill readily available for engineers and technicians around the world. However, there are multiple challenges when it comes to learning PLC programming: high complexity of the platforms, costly hardware & software costs as well as low availability of online materials. It’s what allows one to create a set of instructions in order to control different devices, pieces of machinery and entire manufacturing plants. Introduction to Allen Bradley RSLogix 5000 PLC programmingĪllen Bradley RSLogix 5000 PLC Programming is a highly desired skill in industrial automation. It allows us to make changes before the circuit is implemented, reducing the risk of errors and accidents. And seventh, it helps to identify potential risks and hazards associated with the circuit program. Thus, it provides greater flexibility in experimentation. Sixth, it allows for testing different scenarios without physical changes to the control circuit. Why? Because physical testing can be affected by external factors. Fifth, it provides a more accurate representation of the circuit's behavior than physical testing. Fourth, you gain an understanding of how the program works, how it interacts with various inputs, and how it produces outputs. Third, it allows for the testing of the circuit program without the need for actual hardware, which can save time and resources. Second, you can identify design flaws and adjust parameters to improve the circuit's performance and safety.

First, it allows for error detection in the control circuit program before it is implemented in real-life situations. Mastering the simulation process in Siemens Logo PLC can provide several benefits.

0 kommentar(er)

0 kommentar(er)